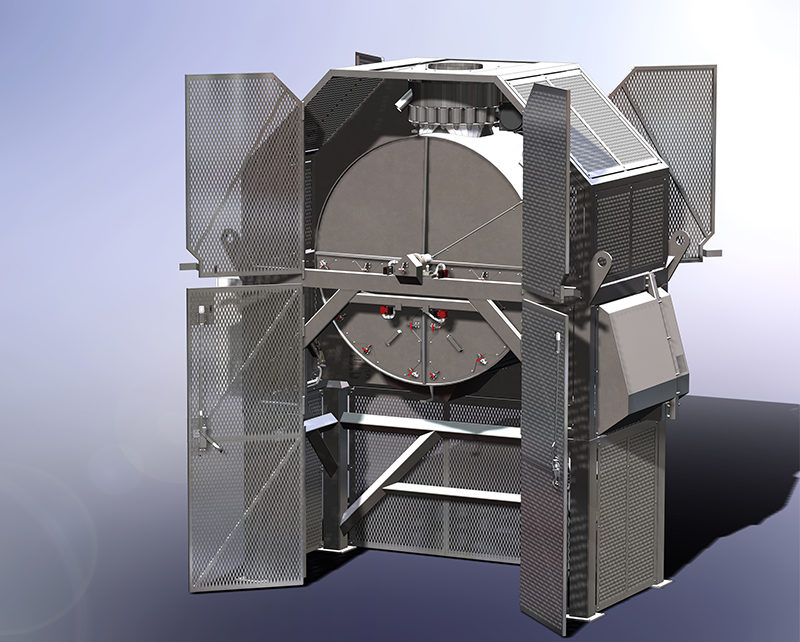

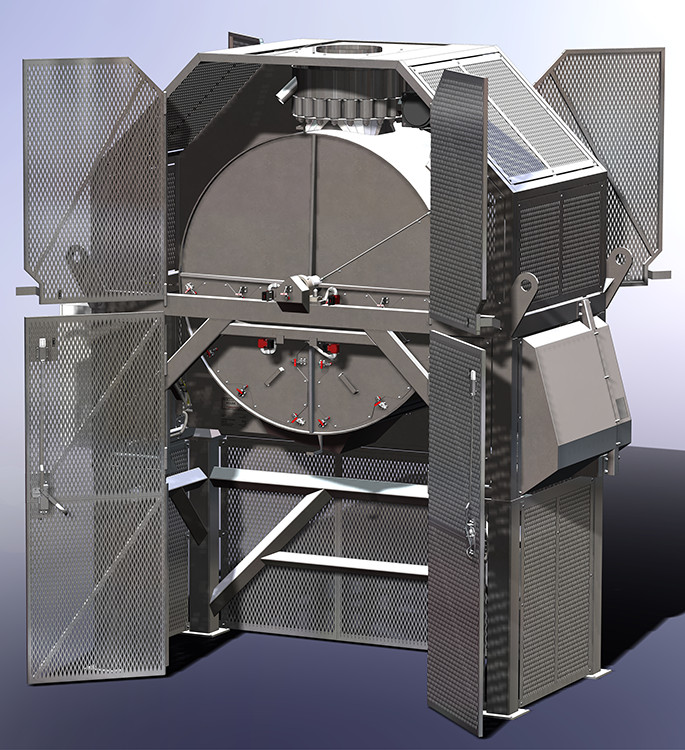

Mk VIII Rollo-Mixer® Dry Blender

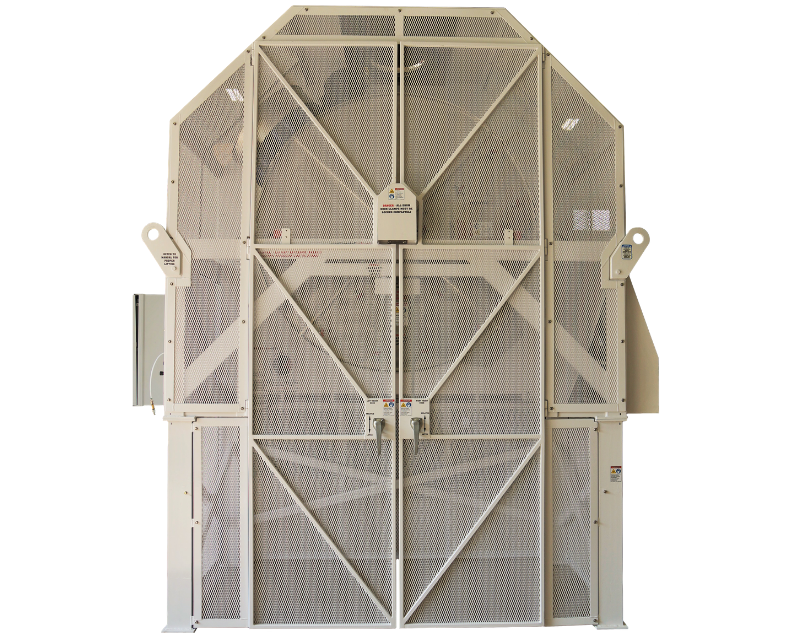

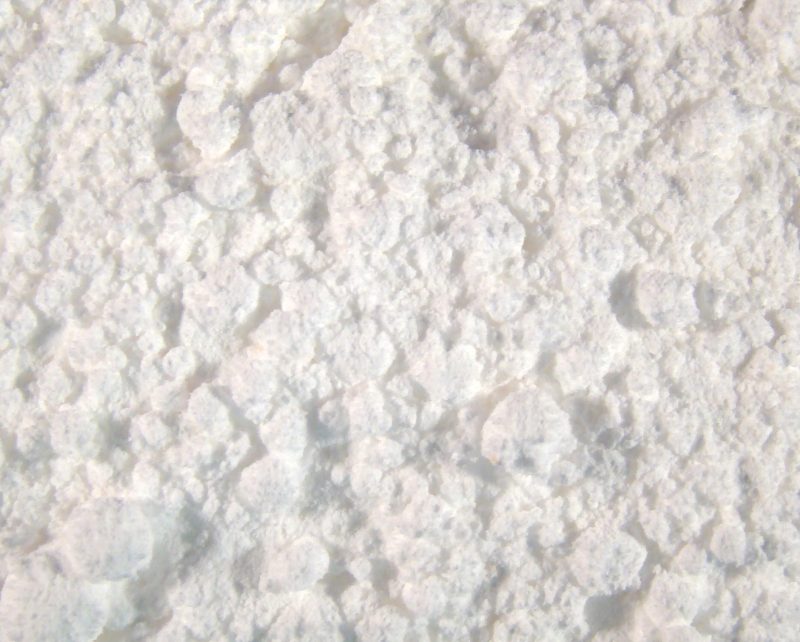

The Mk VIII Rollo-Mixer® is a dry blender designed for uniformly blending dry food grade powders vitamins, nutraceuticals, sports drink powders and dietary supplement powders. Data shows the Mk VIII Rollo-Mixer® to be one of the best dry powder blenders for mixing supplement and food powders. It has been setting high standards in the contract manufacturing and dietary supplement industries for many years now. Tests have proven and results have shown the Mk VIII to be superior for uniformity, clean-out and overall efficiency than typically used dry powder blenders in those industries such as V, cone, and ribbon or paddle blenders.

This Mk VIII design is excellent for high purity batch mixing applications, where cleanout and easy access are critical for quick product change, such as: nutritional powders, nutraceuticals, dietary supplements, powdered drink mixes, supplement powders, and other food grade powders. Also, metal powders, plastic piping & tubing and refractory ceramic powders.

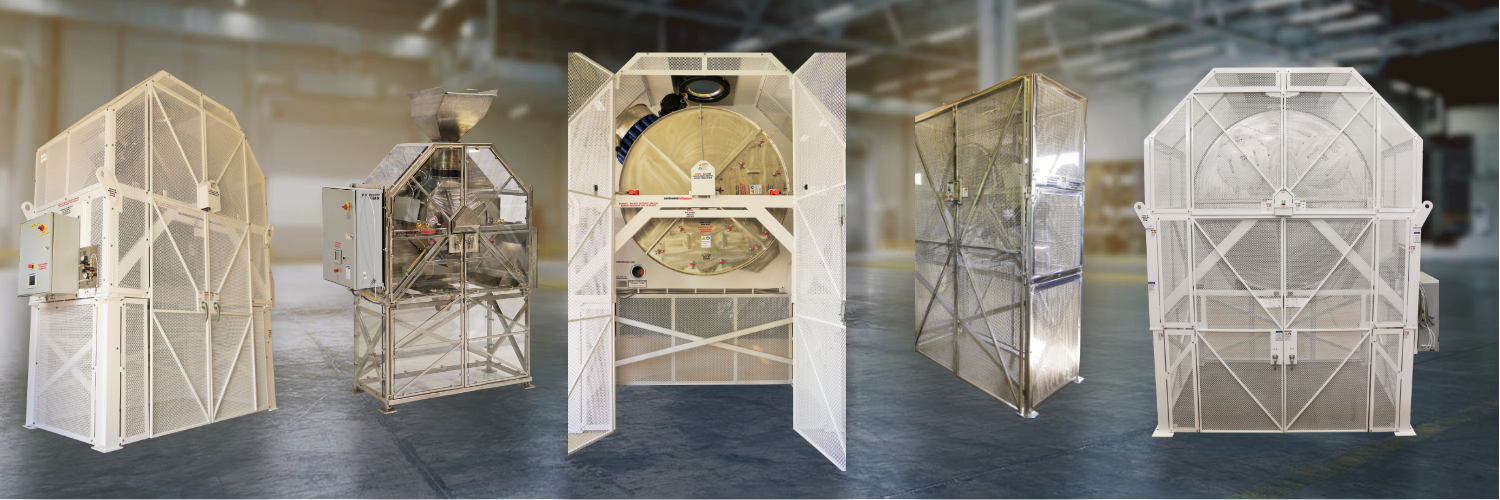

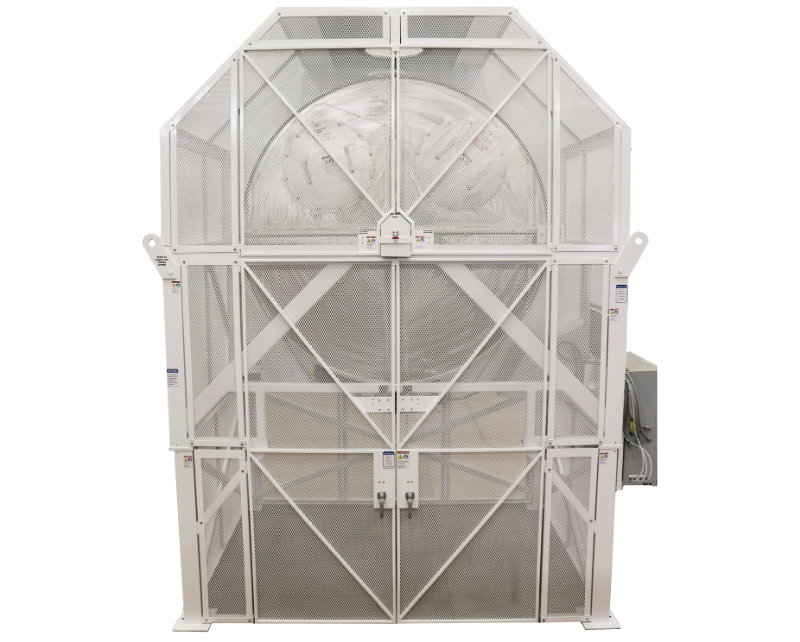

- Mk VIII Photos & Videos

- Food grade package for high purity dry powder mixing

- Blend micrograms into hundreds of lbs uniformly in minutes

- Test proven superior uniformity & cleanout to V & cone blenders

- Consistent uniform mixing in minutes

- Rinse, clean & dry in under 15 minutes

- Available in 9 sizes, from 3.5 to 400 cu ft

- Mk VIII Features & Accessories

Mk VIII - Media Gallery

Mk VIII - Features & Accessories

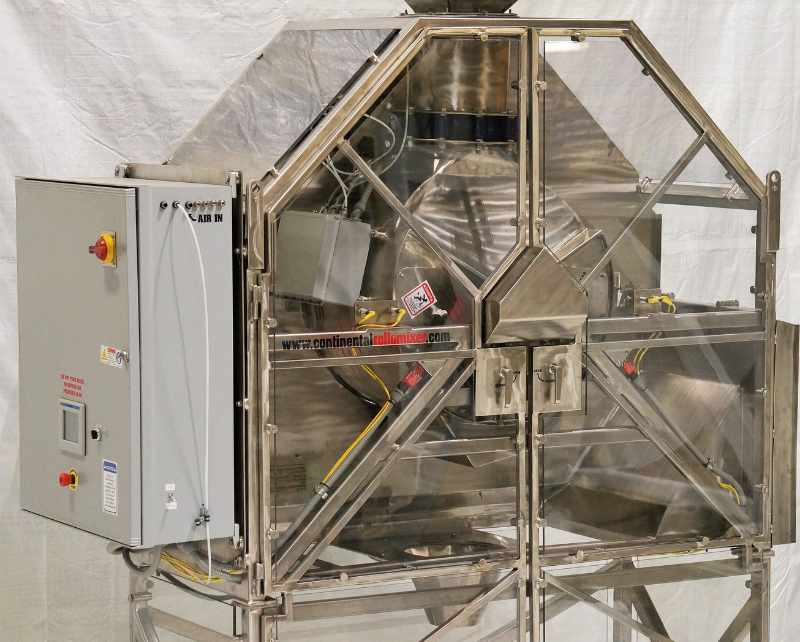

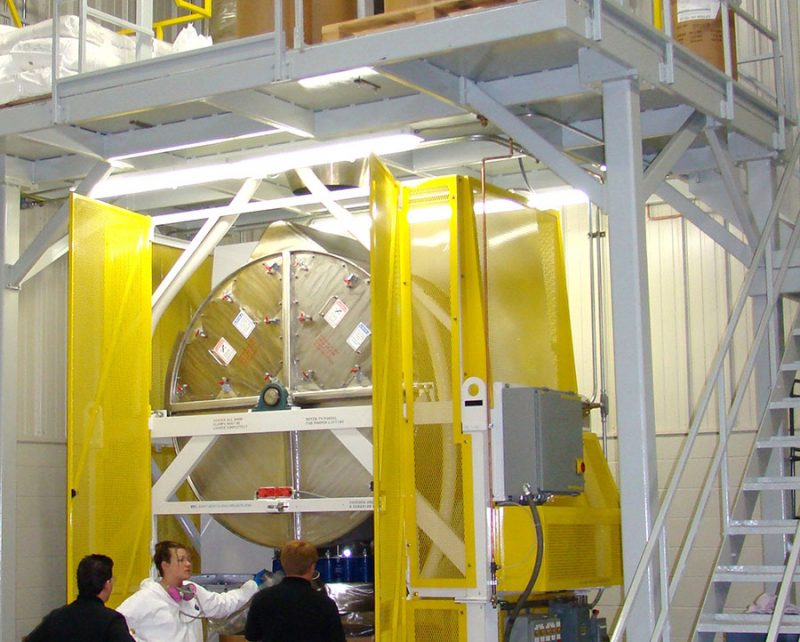

Loading

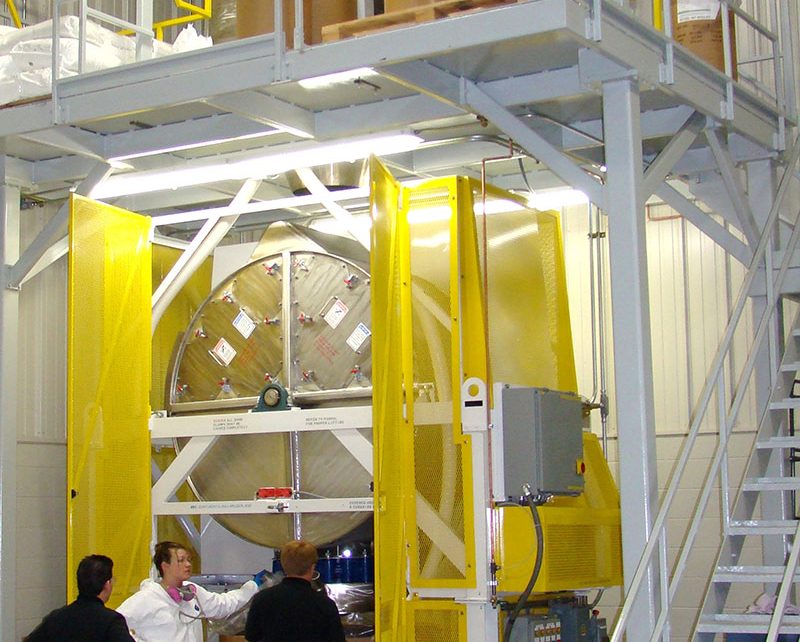

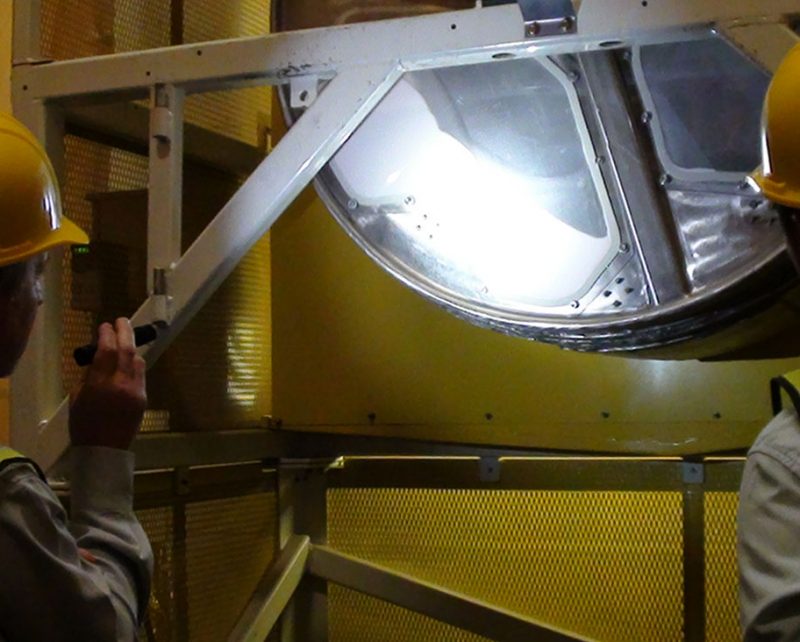

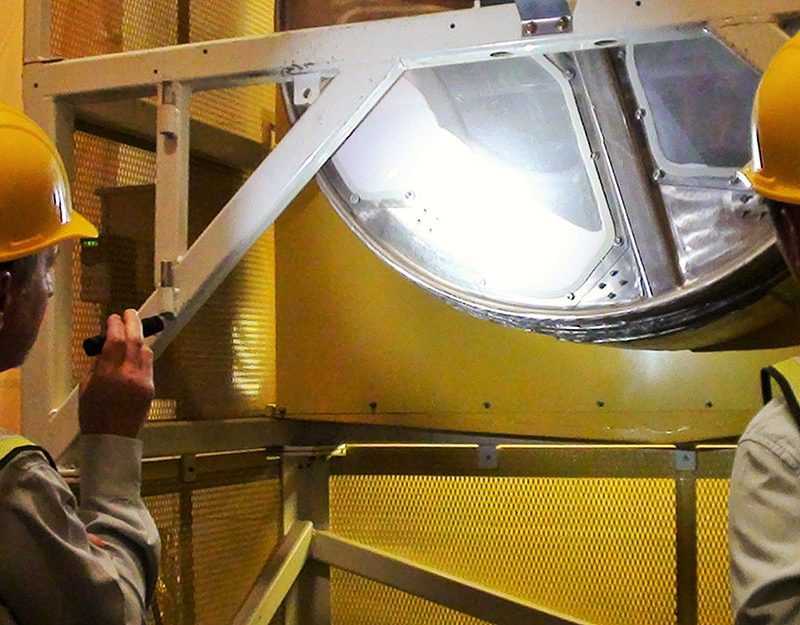

The Mk 8 Rollo-Mixer is designed to receive material by gravity at the 12:00 position, shown above. Bag & barrel stations are used to charge the mixer, and can be fed through de-lumpers. The innovative retractable seal design, allows for a safe, smart, dust-free load in cycle.

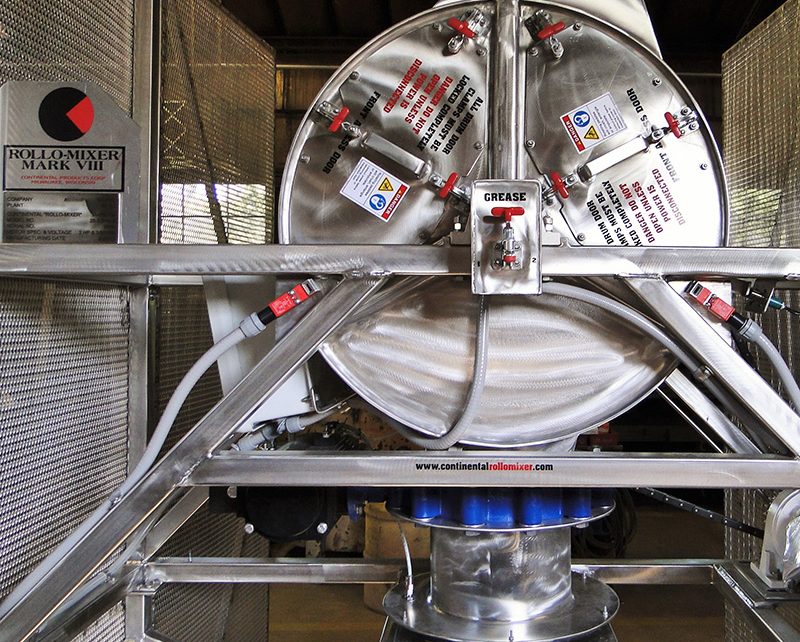

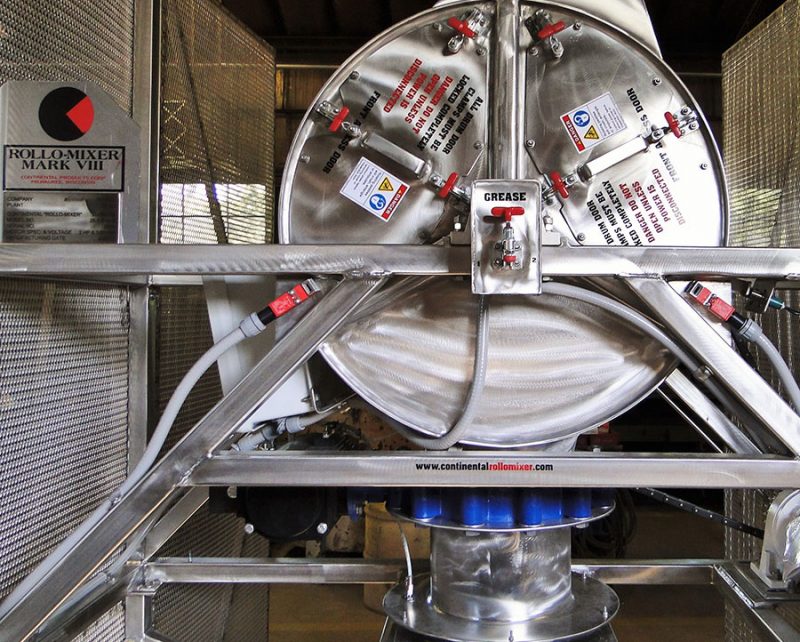

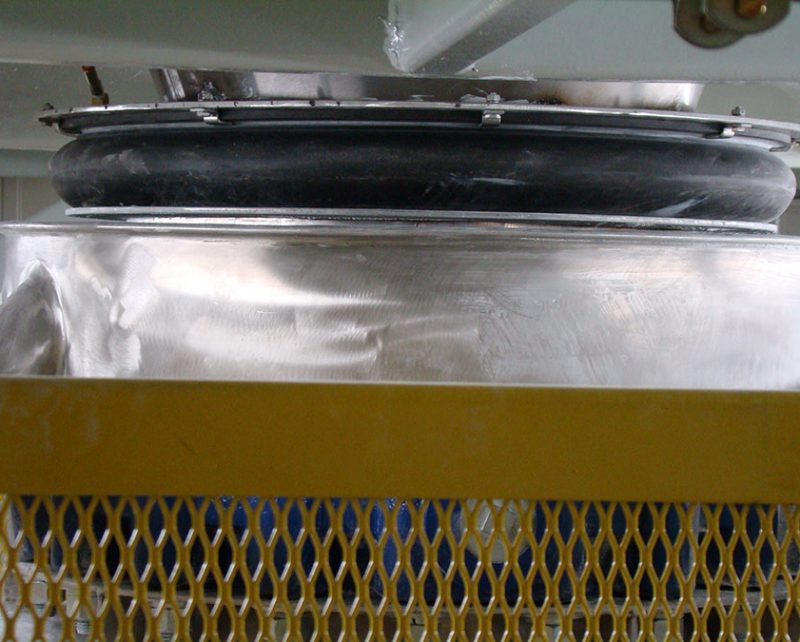

Discharge

After uniformity is achieved, the dry powder mixer is ready to discharge the batch in the 6:00 o’clock position. A programmable butterfly valve is adjustable from 0–100% open, giving full control of product flow. The retractable bladder seals against any barrel, tote or super sak. As batch is discharged, we allow ventilation for the tote by displacing the air to a dust collector or plant wide system. This provides a dust-free batch cycle on the dry powder blending. Large Mk VIII Rollo-Mixers can discharge 2,000 lbs in 8 seconds. Discharge is 100%.

Testimonials

The Mk VIII Rollo-Mixer® was more uniform and cleaned out better than out V and Cone benders.

The best dry blender we have found and we’ve had them all.

The Mk VIII gives us batch to batch uniformity & complete discharge. We rinse & clean in under 15 minutes.

We blend batches with 80 ingredients where we can uniformly add 10 international units of a vitamin into hundreds of pounds,”

Additional Information

Materials of Construction Finishes Available

(material contact points)

- 304 L Stainless Steel

- Food Grade Package

- 80 or 150 grit Polished Stainless Steel finish

- Carbon Steel – High Release Finish

- Abrasion Resistant Plate

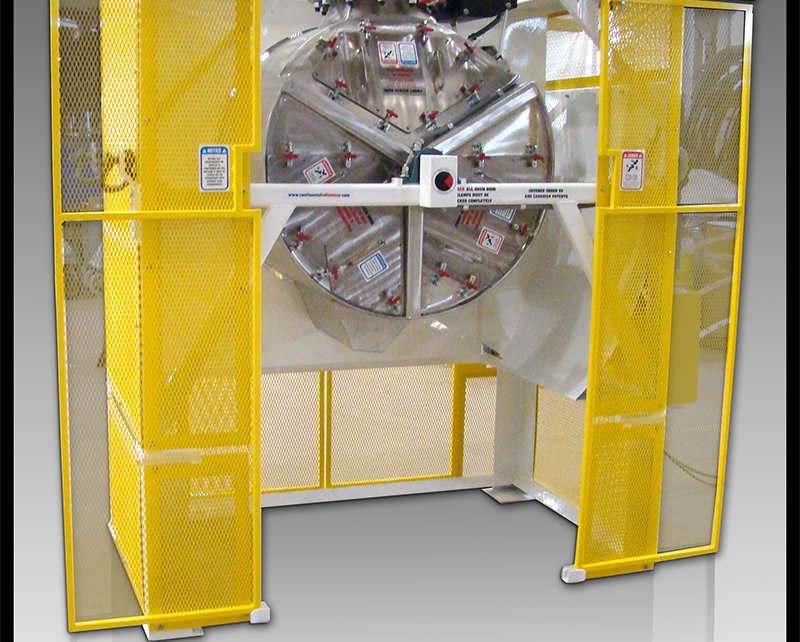

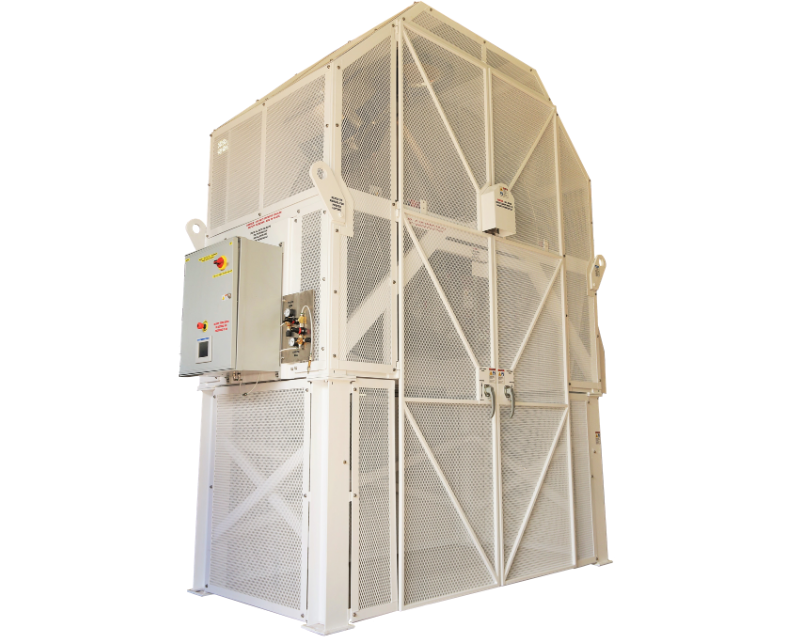

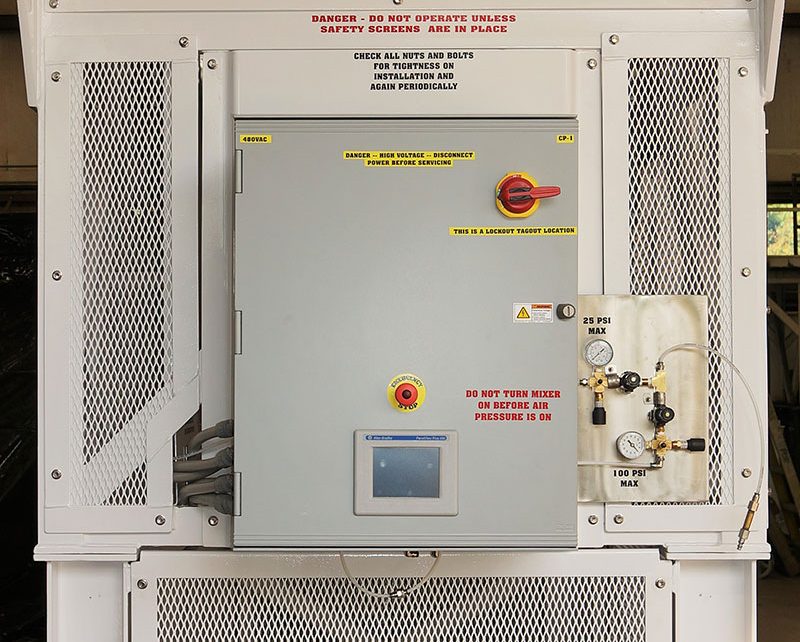

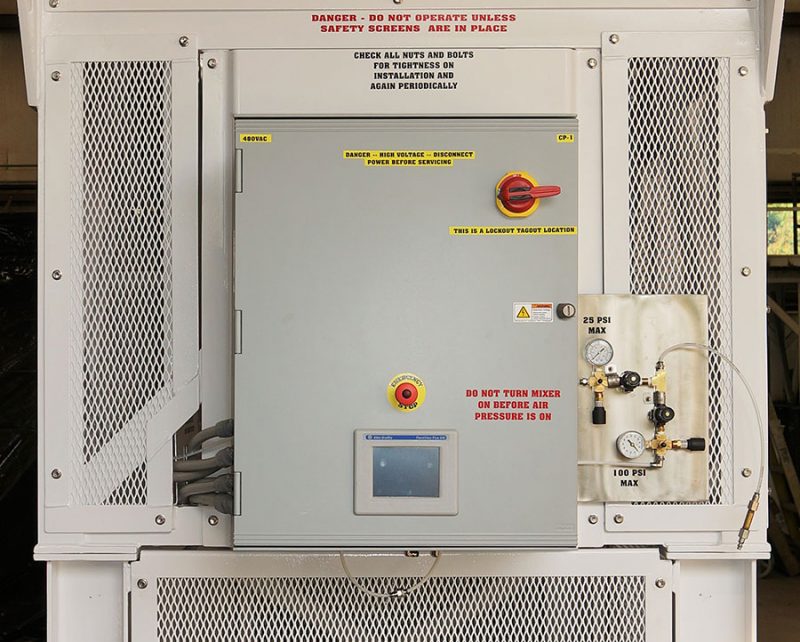

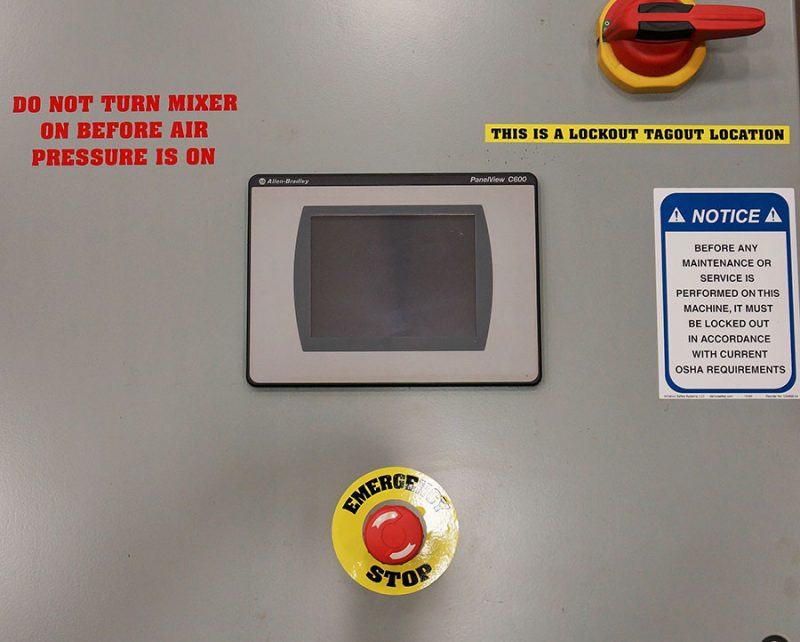

Safety & Maintenance

- State of the art safety switches

- FDA approved Painted Carbon or Stainless Steel Guarding or Lexan

- Accessible Zirk fittings

- Automatic chain oiler

Standards

- CE

- CSA

- NEMA 12,

- NEMA 4x

- Class II, Div. 1 & 2

Mk VIII Series & Sizes

Available in 9 sizes from 3.5 to 400 cu ft. Contact us for dimensional specifications.

- 28 Series (3.5 ft³)

- 31 Series (10 ft³)

- 50 Series (25 ft³)

- 62 Series (33 ft³)

- 74 Series (75 ft³)

- 86 Series (100 ft³)

- 98 Series (150 ft³)

- 101 Series (200ft³)

- 120 Series (300 ft³)

Load Volume Calculator

Test Your Product

We invite you to our test facility in Wisconsin to run trials with the 5 or 10 cu ft Mk VIII Rollo-Mixers®. Watch your products be uniformly blended, or treated with liquids in multiple ways exclusively through “Free-Fall Processing”®

Tell Me MoreContact Us Directly

Call us now to discuss your application. We have worked directly with our customers for over 50 years, and are happy to lend our trusted knowledge to your application. We’re here to help you directly from your initial interest, and testing…. to start up and for the lifespan of your Rollo-Mixer®

Contact Us