Surface Treating & Encapsulating powders and granules in the Rollo-Mixer®

The Rollo-Mixer® and its exclusive Free-Fall Processing® provides superior uniform liquid dispersions onto dry particulates for accurate surface treating. We have been involved in many surface treating and fine powder processing applications over the years, but none like the glass bubbles we successfully coated for our customer in 1999. This is an ideal model for surface coating because we are spraying a liquid onto a surface that does not absorb — in essence the opposite of impregnating. These hollow, spherical glass bubbles are only 2 to 10 micron and weigh only 6 to 10 lbs/ft3. They are used in low density filler applications for the automotive, petrochemical and aerospace industries.

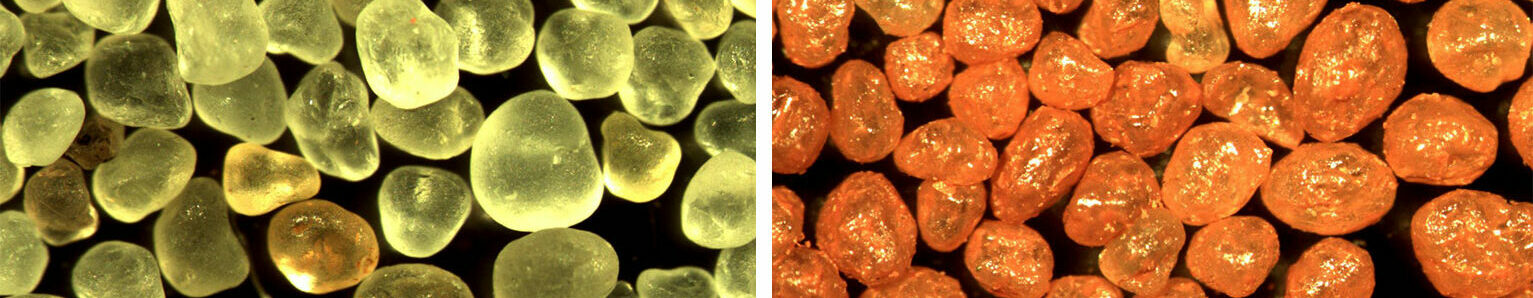

The goal was to evenly distribute a low inclusion (.025 %) liquid solution throughout all of the surface area of the bubbles. The amount of surface area to coat is enormous. Free-Fall Processing® exposed all of the surface area of the glass bubbles without damaging any of the fragile particles. Encapsulating powders to granules with a binder is an exciting process the Rollo-Mixer® is well suited for, because it requires a combination of mixing and coating in one. In one application, the goal was to encapsulate or encase the vitamins onto the rice by spraying the binder in free-fall. Because of the gentle, distributive mix action the vitamin powder and rice particles are uniformly mixed. The process sprays food glue into a uniform free-falling curtain and sealing the vitamins around the rice.

Surface Treating & Encapsulation - Media Gallery

Recommended Rollo-Mixers ® for Surface Treating & Encapsulation

Mk VI

Features & Benefits

- Uniform Batch Mixing & Blending in under 3 minutes

- Award winning liquid addition Free-Fall Processing®

- Available in 51 sizes from 3.5 to 1,286 cu ft

Mk VII-1

Features & Benefits

- Uniform Mixing and Blending in under 3 minutes

- Precise liquid addition – featuring Free-Fall Processing®

- Versatile Solids Processor – available with heating & cooling capabilities.

- Available in in 51 sizes from 3.5 to 1,286 cu ft

Mk IX

Features & Benefits

- Premier Batch Coater for Slow release fertilizers

- Ability to Heat / Coat & Cool Various Substrates

- Pilot & Production Coaters Available

- Batch to Batch Reproducibility

- Available in 10 sizes, from 3.9 to 297 cu ft

A World Leader in Rotary Drum Mixing, Blending, and Coating Technology

We’ve been leading the way in innovative solutions for mixing, blending and coating since 1960. We carry a series of premier rotary drum batch mixers which deliver superior results across many industries. Working directly with our customers, we are with them every step of the way to make their products better than ever before.

Uniform Mixing

Gentle Blending

Award winning coating technology

Batch to Batch consistency

Improve Quality of Finished Products

Increase Production

Test Your Product

We invite you to run trials with a 5 or 10 cu ft Rollo-Mixer® at our facility in Wisconsin. Continental will create a private video of the test, exclusively for your review. Viewing windows allow you to watch the blend. Microscope pictures showcase why Free-Fall Processing differentiates the Rollo-Mixer from other methods of liquids to bulk solids. See your liquids evenly applied in the Rollo-Mixer®

Tell Me MoreCall Us Directly

Call us now to discuss your application. We have worked directly with our customers for over 50 years, and are happy to lend our trusted knowledge to your application. We’re here to help you directly from your initial interest, and testing…. to start up and for the lifespan of your Rollo-Mixer®

Contact Us