Blending and Coating Rubber Products in the Rollo Mixer

One of the most challenging mixing applications we encountered involved blending nitrile rubber with powder additives. The Rollo-Mixer’s dynamic mix action divides and combines these materials over 25 times per revolution while maintaining a uniform mixed product to down-line processing equipment. Not only do the two ingredients have a wide variance in particle size, but keeping them mixed while feeding the extruder is critical to producing a uniform TPE pellet. The Rollo-Mixer is a reliable workhorse applications include post-blending thermoplastics used in hundreds of everyday products. Automotive parts like window and door seals are made from these versatile rubber pellets.

Request More InformationRubber Products Applications

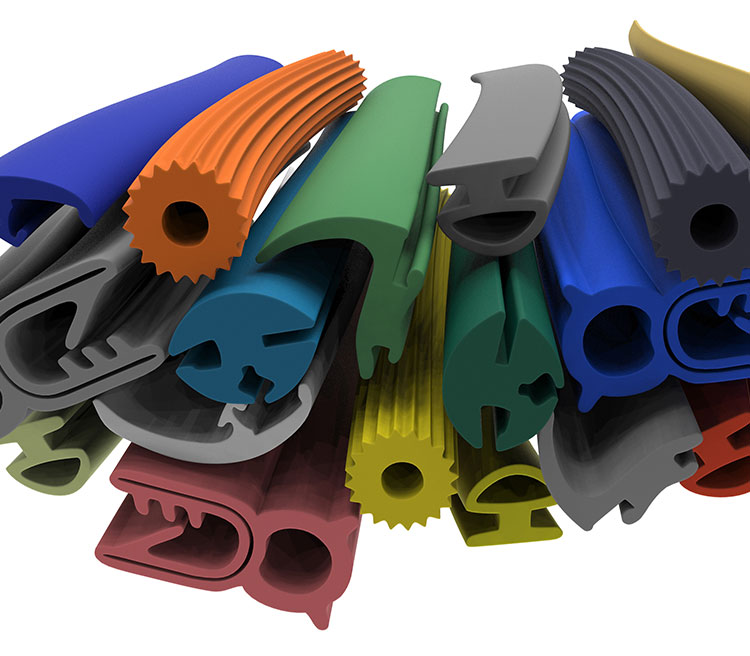

Rubber Product Samples made with Rollo-Mixers®

Thermoplastics are physical mix of polymers (plastic powders and a rubber) which are engineered to perform with the rigidity of plastics and the elasticity of rubber. Global leading manufacturers use Rollo-Mixers for blending thermoplastics for an even dispersion of their extruded pellets. TPE pellets become flexible hoses, cable, toothbrushes, insoles for shoes, snowmobile skis and much more. Crumb rubber is also blended and/or treated in our industrial rubber mixers for use on synthetic sports fields.

View More Samples

Recommended Rollo-Mixers® for Rubber Products

Mk VII-1

Features & Benefits

- Uniform Mixing and Blending in under 3 minutes

- Precise liquid addition – featuring Free-Fall Processing®

- Versatile Solids Processor – available with heating & cooling capabilities.

- Available in in 51 sizes from 3.5 to 1,286 cu ft

Rubber Products - Media Gallery

Test Your Product

We invite you to run trials with a 5 or 10 cu ft Rollo-Mixer® and take samples with your Rubber powders and pellets at our facility in Wisconsin. Watch as your materials, of dissimilar densities and particle sizes, are uniformly blended together for perfect, even extrusions.

Tell Me MoreCall Us Directly

Call us now to discuss your application. We have worked directly with our customers for over 50 years, and are happy to lend our trusted knowledge to your application. We’re here to help you directly from your initial interest, and testing…. to start up and for the lifespan of your Rollo-Mixer®

Contact Us